The installed system at Penrhyn castle could only operate in one of the proposed configurations, configuration 2, shown in Figure 1. The operation was observed from January 24th to March 21st, however the kitchen only opened for visitors on February 17th. The system showed a reduced heat demand from the biomass boiler, equivalent to 594 kWh per year, when extrapolated. This is equivalent to a reduction of about 215 kg technical Ce emissions. However, as it is replacing biomass, only 9 kg of these qualify for the company reporting.

Figure 1. Operating configuration at Penrhyn castle

Figure 2. The DWHR system at Penrhyn castle

The system increased the incoming water temperature from an average of 11.75°C to 17.59°C, as shown in Figure 3. After March 21st the operation was halted due to the COVID-19 crisis.

This is smaller than the predicted recovery, due to the lower water consumption of the kitchen during this operation period than at the time of the feasibility study (293.05 l/day vs 652.5 l/day). A simpler configuration, where the incoming fresh water is simply preheated, was deemed more profitable. This is mainly due to its smaller capital investment, and the fact that no additional pumping is required.

Figure 3. Incoming and preheated water temperature at Penrhyn castle

The system at ABP operated for a full week at the outlet of the Dissolved Air Flotation unit (within the wastewater treatment system), as shown in Figure 4 and Figure 5.

Figure 4. The DWHR unit at ABP

Figure 5. The wastewater intake at ABP

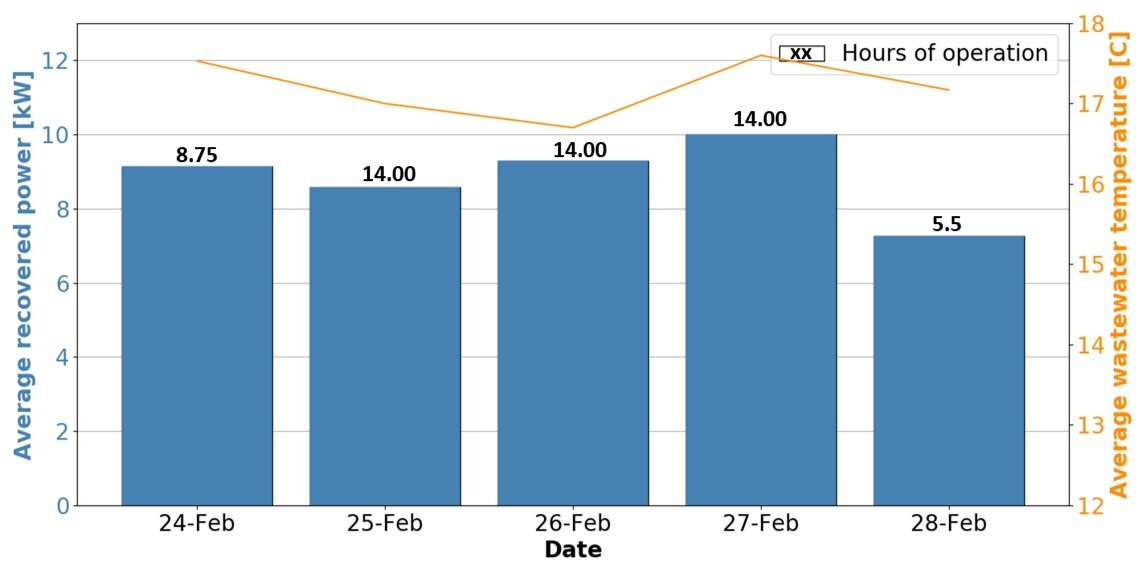

The unit recovered 120-140 kWh per day, at an average heating power well above 8.5 kW, as can be seen in Figure 6

Although these results are encouraging, multiple challenges occurred because of the experimental parallel nature of the DWHR unit. At first, the wastewater was pumped from the DAF outlet into the experimental unit, back into the inlet sump. However, this required an increased forward pumping of the wastewater in the treatment system, increasing pumping consumption and required chemical dosage. To counteract this, the system was adapted and installed in-line, after running through the experimental unit, the wastewater was pumped back up to the DAF outlet. However, this changed the hydraulic characteristics of the system, moving from an open gravitational system, to a pressurised system. The experimental unit, being designed for operation in the former, could not withstand the additional pressure associated with the latter. Adaptations to the system were ongoing, but interrupted by the COVID-19 crisis.

Figure 6. Operation of the DWHR unit at the DAF outlet at ABP, Cahir