Micro-hydropower (MHP)

The classification of hydropower plants according to the power output is a matter of size, as shown in this table.

The Dŵr Uisce project is focusing on the development on micro-hydropower (MHP) installations, which ranges from 5 kW to 100 kW.

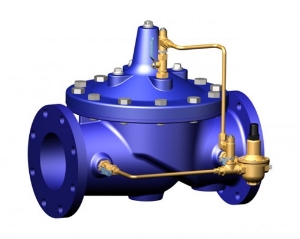

Pressure Reducing Valve (PRV)

Reduces pressure to a preset level downstream of the valve with the goal to keep pressure levels within a determined range throughout the network.

The Dŵr Uisce project points PRV locations in water networks as potential sites for energy recovery.

Fig. Schematic of a PRV.

Fig. Example of a PRV.

Smart Network Controls

Fig. Water scheme including transmission and distribution systems (left) and generic water distribution network for model testing.

Sensing, actuation, and control functions are considered in order to describe and analyse a situation, and make decisions based on the available data in a predictive or adaptive manner, thereby performing smart actions. The deployment of smart network controls in Dŵr-Uisce aims at identifying energy recovery locations and optimise energy performance through the installation of turbines with a dual pressure reducing and energy production function.

Pump as Turbines (PAT)

Fig. Energy recovery in a water network using multiple PATs (Source: KSB).

Pumps as Turbines (PATs) are an unconventional solution for hydro power generation adapt to fit in many scenarios when a conventional turbine unit would not be suitable. Physical behaviour of PATs is similar to that of Francis turbines, but without possibility for flow regulation. Within last decades large numbers of PATs have been studied and implemented as power generators in many contexts like small hydropower schemes with low-head properties, water supply systems (WSS) and industrial applications as replacements of throttling valves. In particular, they proved to be very effective if used for micro hydro off-grid plants and in-pipe energy recovery.

Drain Water Heat Recovery (DWHR)

Fig. Reducing the heating energy consumption through DWHR.

Currently, hot water from showers, dish washers, washing machines and other hot water consuming appliances is most often flushed through the drain, leaving a significant part of the energy unused. In modern building it is the most important source of energy loss. Drain Water Heat Recovery (DWHR) is the collective name of technologies attempting to utilize this untapped potential. These technologies help in both reducing the fuel and energy consumption related to heating, and allow for the application of wastewater source heat pumps, considered a renewable source of heat. The Dŵr Uisce project aims at quantifying the potential impact of DWHR technologies in Ireland and Wales with respect to the environmental impact of heating and with respect to heating costs. A prototype of a DWHR system is a project deliverable as well.

Environmental impact assessment and eco-design

Fig. Stages of the life cycle of a heat recovery system suitable for heat recovery from waste water e.g. from a commercial kitchen

Fig. Comparison of the global warming impact (carbon emissions) from recovering heat from waste water of a kitchen vs. heating the water with other energy sources: Recovering heat saves carbon emissions even when replacing renewable energy

Every human activity and every manufactured product carries an environmental footprint – this is no different for the use of water. Water is pumped during abstraction or in industrial processes, water is heated for our showers or in making food. This requires a significant amount of energy. Did you know that 90 % of the energy invested in domestic water is consumed to heat water in households?

Our environmental impact assessments, here through the application of life cycle assessment methodology (LCA), look at the footprint from using water. One focus is on water use in the food and drink sector, for example commercials kitchens or brewing and distilling. We hope to identify how this water use footprint can be reduced, for instance through recovering heat from process or waste water (see above). And how do we design the equipment for heat recovery in an eco-friendly way? All this is part of the environmental impact assessment work package.

If you want to know more about the LCA methodology…

LCA is a method of quantifying the environmental burdens for a product or service through its life cycle starting with mining or planting the raw materials to the product’s disposal or recycling. A detailed database of raw materials and energy processes is required to accurately report the environmental burdens. The results can be used to compare different products, in the case of this project, comparing options for water use and treatment or heat recovery solutions.

History of Hydropower

Energy exists within any flowing water course, natural or man-made, and this energy can be extracted using hydropower technology. This concept of transferring this energy or 'power, from flowing water has been a longstanding tradition dating back to the earliest water wheels (used for milling, mining, water supply and irrigation) over 2,000 years, to the Roman, Greek and Han dynasties. With significant technological advancements in the 20th century, the evolution of hydropower escalated as a source of electricity led to a new scale of utilisation for this valuable energy resource. Today, hydropower remains one of the most efficient forms of energy production, with in excess of 90% efficiency typical of most well designed turbine installations.

Fig. Example of Traditional Water Wheel.

Energy in Water

The energy extracted from hydropower facilities is derived from the potential energy, which is transformed into kinetic energy and is a function of two parameters; head and flow. The head is the energy per unit weight (or unit mass) of water. This static head is proportional to the difference in height through which the water falls. The volumetric flow of the water is also proportional to the amount of energy that can be extracted from a water source.

Turbines

There are two main types of turbines; Reaction and Impulse turbines. The selection of a turbine to match head and flow conditions is an important factor when installing a turbine at a hydropower site. The following sections give a summary of the two main turbine types;

Reaction Turbine

Reaction turbines are the most common type of turbines. They generate power from exploiting oncoming flows, as the turbine propeller blades absorb the energy from the moving water. The main types of reaction turbines include; the Francis turbine, the Propeller/Kaplan turbine, the Tyson, Gorlov and China turbines. Also, the development of reverse pumps or pump as turbines (PATs) are used as reaction turbines. Low flow and high head conditions are the most suitable for reaction turbines and the typical turbine is used for enclosed water flows.

Fig. Selection of Reaction Turbines

Impulse Turbine

Impulse turbines are typically more suitable for micro-hydropower installations e.g. run-off-river applications. This type of turbine has several benefits in comparison to the reaction turbine; it tolerates particles in flow, better access to parts, easier to fabricate and a better part-flow efficiency. The disadvantage of the impulse turbine is its unsuitability for low head sites. The Pelton, Turgo, Crossflow and Archimedes are the most well known types of impulse turbines and work under the principle of a jet of water acting upon buckets or runners on a wheel, which is rotated due to the force of the moving water.

Fig. A range of Impulse Turbines

Calculating the Power Potential

The potential power available at a hydroelectric facility can be estimated based on the hydraulic head and flow rate in the water course. The power available from falling water can be calculated from the flow rate and density of water, the height of fall, and the local acceleration due to gravity. In SI units, the power is:

P = ηρQgh

P - power (kW)

η - turbine efficiency

ρ - density of water (kg/m^3)

Q - flow (m^3/s)

g- acceleration due to gravity (m/s^2)

h - head of water (m)

e.g. Power is calculated for a turbine that is 85% efficient, e.g. water density of 1000 kg/m^3; a flow rate of 80 m^3/s; gravity of 9.81 m/s^2; and a net head of 70 m. In SI units: Power (MW) = (0.85 x 1000 x 80 x 9.81 x 70)/10^6 => which gives 46.7 MW

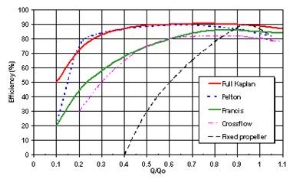

Turbine Selection

As previously stated, the selection of a suitable turbine is based on flow and head characteristics for a water course. The following plot is used as a guideline to decide on the most suitable turbine type for a specific site.

Fig. Profile of different turbines based on flow and pressure characteristic

Feasibility Study

Hydropower energy recovery in water supply networks is one of the targets of Dŵr Uisce project. In this context a key element is the demonstration of the micro-hydropower potential in real networks. For this purpose, the feasibility of implementing this technology is assessed in water supply schemes.

Fig. Case-study of water distribution network with potential MHP sites.

Fig. Power available in a range of energy recovery sites.