Eco-design of Energy Recovery Systems

Taking a life cycle approach to developing the technology platforms that will be deployed at the demonstrations sites in the project, the resulting output will be shaped into an eco-design toolkit that provides guidance to ensure that energy recovery systems are low-carbon and resource efficient, and takes a circular economy approach to design and implementation of these technologies.

An eco-design toolkit

The integration of eco-design concepts within the design phase of our technological solutions, and indeed taking a circular economy approach to our project as a whole, we can deliver further environmental and socio-economic benefits, and this has wider applicability to all infrastructure projects. The development of an eco-design 'toolkit' specially designed to cater for those working in the water sector, will help support carbon and resource efficiency in design, embracing a modular approach to water services of the future. The tool will promote greener materials and alternative construction or manufacturing processes, and it will be applied in the development and demonstration of our technology platforms.

We will also examine construction practices in the water distribution sector to compile general guidelines and extend the scope of the toolkit for applying eco-design of new infrastructure. This will add value to planned investments, as highlighted earlier in the strategic fit section of this proposal.

New Findings on Eco-design of Heat Recovery Systems

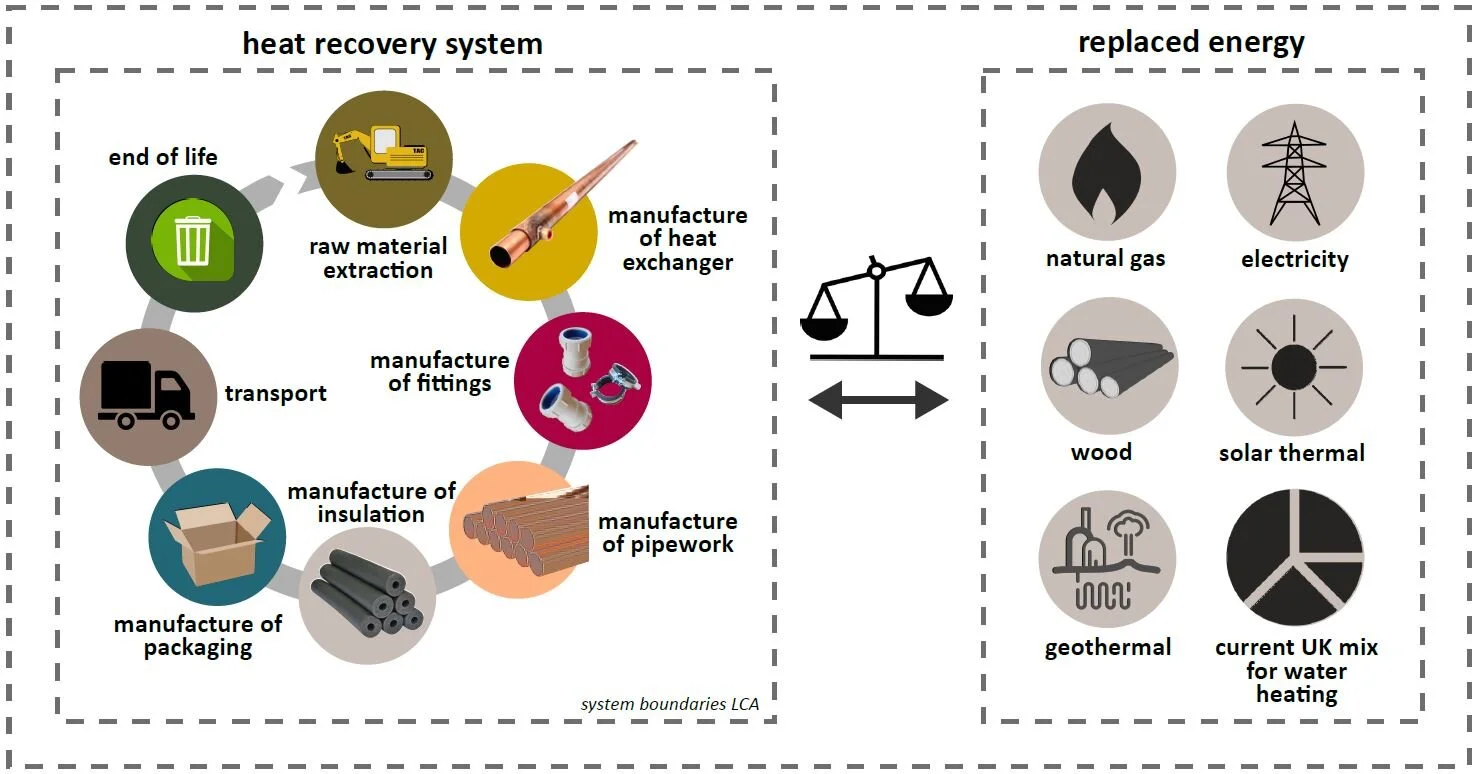

A first study has been conducted on how to sustainably recover heat from commercial kitchen’s drain water, based on experience with the Penrhyn Castle demonstration site. We determined the environmental impacts associated with manufacture and installation of a drain water heat recovery system comprising all necessary equipment such as an in-line heat exchanger and connecting pipework and fittings. Through a Life Cycle Assessment, environmental impacts starting from raw material extraction and ending with recycling and/or disposal of the equipment were quantified. The majority of the environmental burden is caused through the manufacture of copper parts such as the heat exchanger, especially when made from primary, rather than recycled, copper. Smart material choice can dramatically reduce impacts: recycled copper or newly developed heat transferring materials such as polymer based heat exchangers, or polyethylene instead of metallic pipework.

The environmental burdens of heat recovery manufacture and installation were then compared to the environmental benefits of reduced water heating achieved through heat recovery. How long does it take for energy savings to payback the environmental footprint of system installation? In the case of the Penrhyn Castle case study, carbon emissions are offset easily within a considered 10 year lifetime of the heat recovery system, no matter if renewable or fossil fuels for water heating are replaced through the recovered heat. We did notice some trade-offs though, when considering other environmental impacts such as resource depletion, owing to large amounts of metal used in heat exchange systems.

Trade-offs can be negated when heat recovery systems are used in kitchens with higher water consumption, where large heat recovery potential offsets all impacts of installation. For a heat recovery system consisting of a copper heat exchanger and pipework of 10 m, full environmental payback within 10 years can be achieved from water consumption rates of about 300 m3 per year. If heat recovery was applied in all UK commercial food outlets, 500,000 tonnes of CO2 equivalents could be saved per year. That is equivalent to taking 260,000 cars of the roads.

This study was published in a peer-reviewed journal: “Emissions down the drain: Balancing life cycle energy and greenhouse gas savings with resource use for heat recovery from kitchen drains”.

System Boundaries and Inventory