Drain Water Heat Recovery in Domestic and Commercial Settings

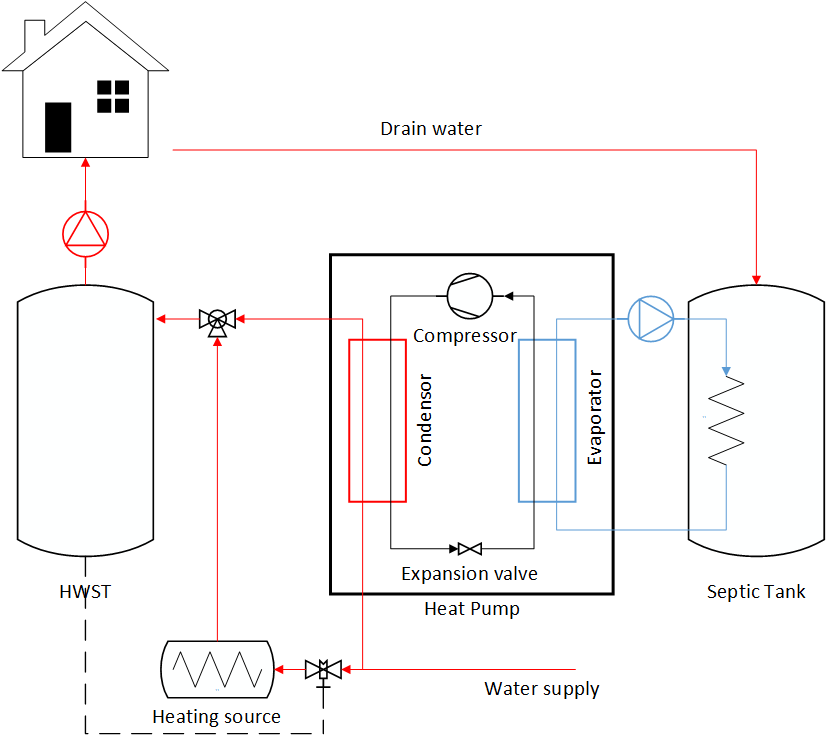

Schematic of Drain Water Heat Recovery system

Much of the energy consumed in heating water for domestic appliances and sanitation is wasted to the drainage system. This waste not only exists in the domestic sector, but also applies to many commercial buildings such as restaurants, hotels, schools, hospitals or leisure centres. The energy efficiency of such processes can be improved through the adoption of Drain Water Heat Recovery (DWHR) systems, as hot waste water passes through a heat exchanger and the heat energy is transferred to incoming cold water streams or to a hot water storage system.

Our research group has been working on investigation of DWHR in the commercial as well as the residential sectors.

In terms of commercial buildings, a DWHR system has been installed at ABP Food Group. The aim of this installation is to recover heat from hot water used during meat processing and reduce overall energy consumption.

A second demonstration site is located at the tourist attraction of Penrhyn Castle in North Wales, where heat is recovered from the drain of the restaurant kitchen. The installation at Penrhyn Castle was the basis for an assessment of the environmental performance of heat recovery systems for drain water from commercial kitchens in the UK.

In residential settings, our previous study showed that there is a timescale mismatch between the heat supplied from the wastewater and space heating consumption. The heat supplied from the wastewater has to be stored using a thermal storage so that it can be used at a later time.

Overall, the installation of Drain Water Heat Recovery system is intended to increase the efficiency of heat consumption. In particular, with the combined application of predictive control algorithms can further augment the heat efficiency.

Lab-scale development of DWHR units

A prototype DWHR system was developed to recover the heat in waste water from commercial kitchen drain water. The system looks to integrate a direct DWHR system with the grease trap. Because grease traps are mandatory in commercial kitchens, the prototype aims to provide financial and space savings through this integration.

Field demonstration of DWHR in the hospitality sector

Field-scale demonstration sites of the developed technology will be deployed in both Ireland and Wales to demonstrate the potential for energy recovery in commercial settings. The task comprises the design, installation and monitoring of the system. Energy savings and CO2 emissions reduction will be monitored. The site will be used for site visits and case study work in the smart specialisation cluster.

Environmental impacts & benefits of heat recovery in kitchens

Taking a circular economy approach, we carried out an environmental impact assessment integrated with eco-design concepts during the design phase of our technological solutions. This approach delivers further environmental and socio-economic benefits, with wider applicability to all infrastructure projects.

Recovering heat from water and by-products in distilleries

Distilleries are excellent locations to study the recovery of heat and the reuse of water as they have considerable heating requirements for mashing and distillations and use great volumes of water, e.g. for cooling.